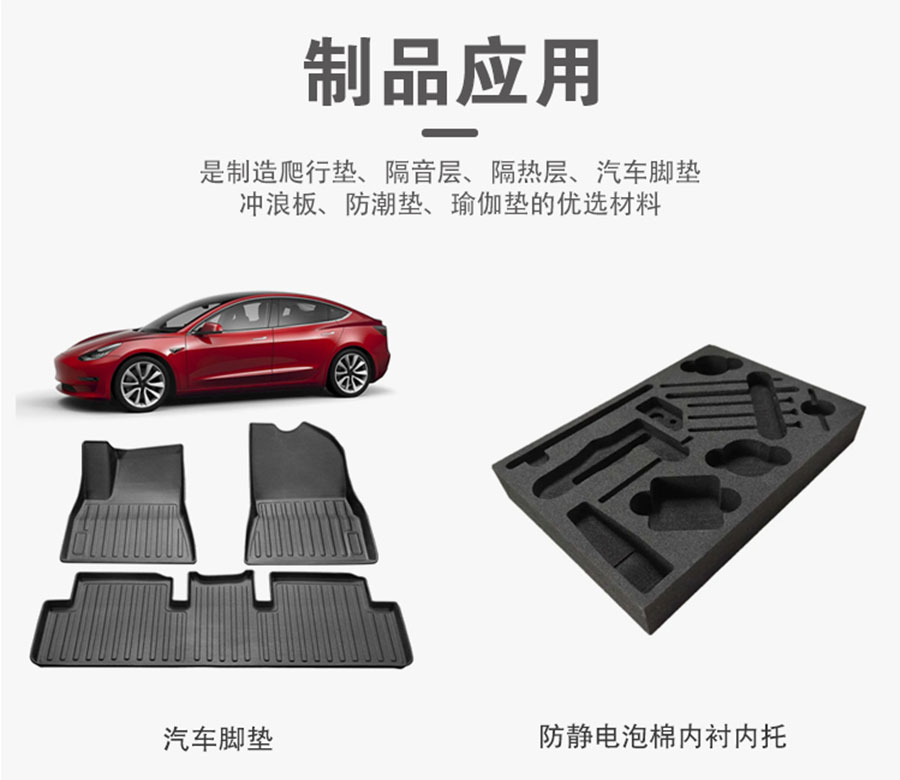

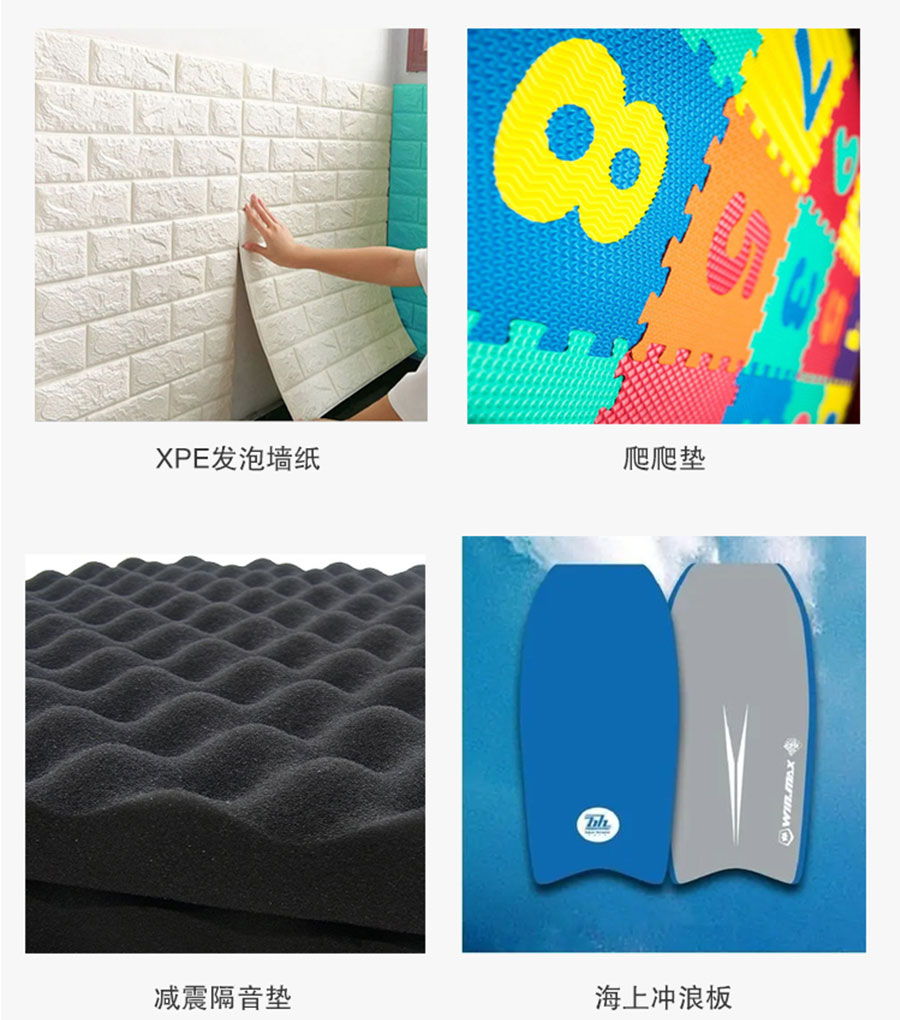

产品介绍:

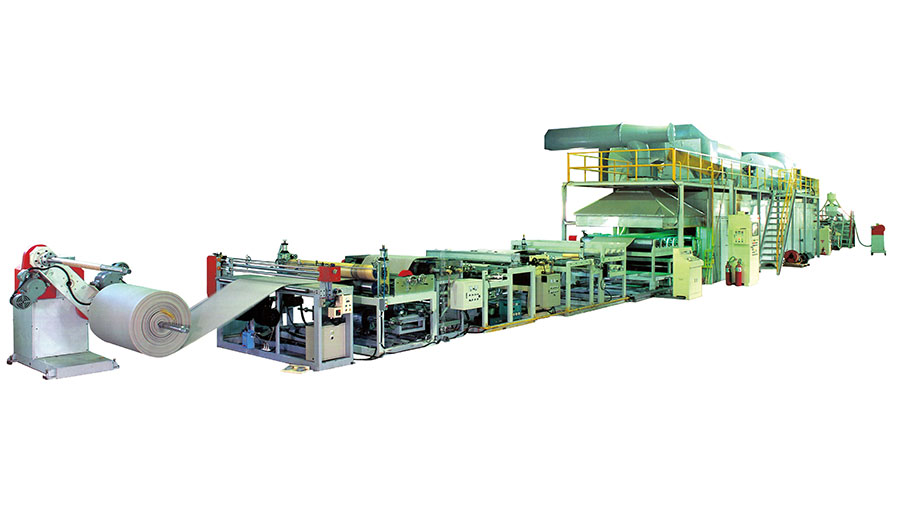

XPE化学交联聚乙烯发泡片材生产线

XPE Chemical Cross-link PE Foamed Sheet Production Line

XPE化学交联聚乙烯泡沫材料是以低密度聚乙烯(LDPE)与乙烯一醋酸乙烯共聚物(EVA)为主要原料,添加发泡剂AC等多种化工原料,经混合、加工、成形,在原料中添加过氧化物交联剂,经过交联反应、再经发泡、定型、后处理等系列加工工艺生产出来的一种具有优异的物理机械性能、外观漂亮、手感舒适、热加工性好的闭孔型泡沫材料。

XPE化学交联聚乙烯泡沫材料具有泡孔细密均匀、强韧、隔热、隔音效果好、耐腐蚀性高、回弹性好、吸水性小、手感舒适等多种优异性能。可广泛适用于汽车制造业、空调制冷业、包装业、建筑、工程、农业、体育用品、娱乐及日常生活等领域。

XPE材质相较于其他PE或者非PE类的材料在耐用性、抗光照、抗物理撞击等方面有着出色的表现,XPE本身化学性质稳定,不易分解,无气味,弹性好。

XPE crosslinked polyethylene foam material is a low density polyethylene (LDPE) and ethylene vinyl acetate copolymer (EVA) as the main raw materials, add foaming agent AC and other chemical raw materials, after mixing, processing, forming, add peroxide crosslinking agent in raw materials, after crosslinking reaction, foaming, shaping, post-processing process of a excellent physical and mechanical properties, beautiful appearance, comfortable, good hot processing high-grade closed-hole foam material.

XPE crosslinked polyethylene foam material has a variety of excellent properties such as fine, uniform, heat insulation, good sound insulation, high corrosion resistance, good resilience, small water absorption and comfortable feel. It can be widely used in automobile manufacturing industry, air conditioning and refrigeration industry, packaging industry, construction, engineering, agriculture, sporting goods, entertainment and daily life and other fields.

Compared with other PE or non-PE materials, XPE material has excellent performance in durability, light resistance, and physical impact resistance. XPE itself has stable chemical properties, not easy to decompose, no smell, and good elasticity.

技术参数:

| 制粒机组Granulation Unit | ||||||

| 密炼机Banburying machine | 机器型号 | Model | TJ-ZL-35L-100×15 | TJ-ZL-55L-120×12 | TJ-ZL-75L-135×20 | |

| 挤出机 | Extruder | Ø35 | Ø55 | Ø75 | ||

| 主机功率 | The main motor power | KW | 55 | 75 | 110 | |

| 产量(约) | Output(approx) | Kg/h | 150-200 | 200-300 | 300-450 | |

| 尺寸(约) | Dimensions (L×W×H)(approx) | m | 2.3×1.6×2.6 | 2.5×1.8×2.8 | 2.7×2.0×3.2 | |

| 造粒机Pelletizer machine | 螺杆 | Screw | Ø100/15 | Ø120/12 | Ø135/10 | |

| 主机功率 | The main motor power | KW | 40 | 45 | 55 | |

| 产量(约) | Output(approx) | Kg/h | 150-200 | 200-300 | 300-450 | |

| 尺寸(约) | Dimensions (L×W×H)(approx) | m | 3.5×1.4×1.4 | 3.6×1.5×1.6 | 3.7×1.6×1.6 | |

| 片材机组 Foamed Sheet Machine | |||||

| 机器型号 | Model | TJ-ZP-120×26 | TJ-ZP-135×26 | TJ-ZP-150×26 | |

| 挤出机 | Extruder | Ø120/26 | Ø135/26 | Ø150/26 | |

| 主机功率 | The main motor power | KW | 110 | 135 | 160 |

| 产量(约) | Output(approx) | Kg/h | 90-120 | 90-120 | 150-200 |

| 尺寸(约) | Dimensions (L×W×H)(approx) | m | 12×3.1×2.8 | 12.5×3.3×3.0 | 13×3.5×3.2 |

| 水平发泡机组Horizontal Foamed Machine | |||||

| 机器型号 | Model | TJ-P-FP-18×1.2 | TJ-P-FP-18×1.5 | TJ-P-FP-18×1.8 | |

| 炉体尺寸 | Oven shell dimensions(L×W) | m | 18×2 | 18×2.3 | 18×2.5 |

| 热量输入 | Heat input | Kcal/h | 28 | 32 | 36 |

| 电力 | Power | KW | 50 | 55 | 60 |

| 蕞大产量(约) | Max.output(approx) | Kg/h | 120 | 150 | 180 |

| 制品厚度 | Thickness of product | mm | 0.5-7 | 0.5-7 | 0.5-7 |

| 制品宽度 | Width of product | mm | 600-1200 | 600-1500 | 600-1800 |

| 垂直发泡机组 Vertical Foamed Machine | |||||

| 机器型号 | Model | TJ-P-FP-(6+5)×1.2 | TJ-P-FP-(6+5)×1.5 | TJ-P-FP-(6+5)×1.8 | |

| 炉体尺寸 | Oven shell dimensions(L×W) | m | 6×1.2+5×1.8 | 6×1.5+5×2.0 | 6×1.8+5×2.3 |

| 热量输入 | Heat input | Kcal/h | 25 | 28 | 32 |

| 电力 | Power | KW | 290+15 | 325+15 | 370+15 |

| 蕞大产量(约) | Max.output(approx) | Kg/h | 120 | 150 | 180 |

| 制品厚度 | Thickness of product | mm | 0.5-7 | 0.5-7 | 0.5-7 |

| 制品宽度 | Width of product | mm | 600-1200 | 600-1500 | 600-1800 |